6825 SW 81 ST Miami FL 33143 305-661-3357

Services

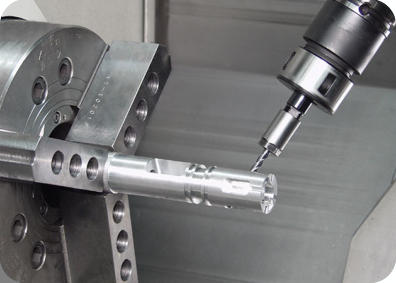

CNC machining

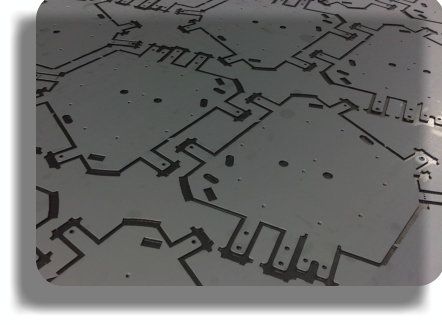

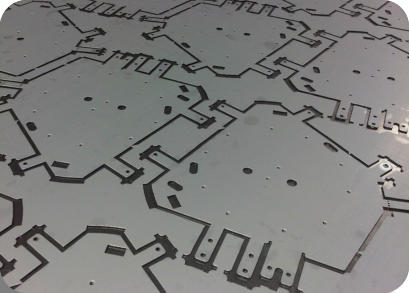

With multiple Lathes, Mills, large Gantry mills and Routers MWL Engineering can handle most projects. From architectural elements to precision parts. We work with all materials. Metals Wood Composites PlasticsLaser cutting

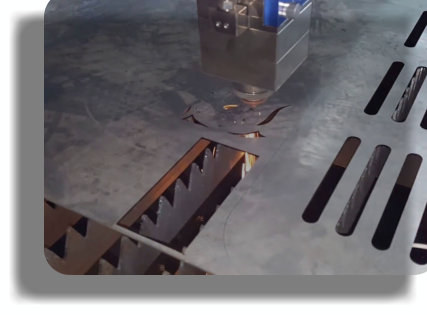

With both Fiber and C02 lasers at our disposal there is not much we cannot cut. With an over sized Fiber laser cutting table 78” X 144” and an open bed C02 we can process materials up to ⅝” thick. Our lasers are designed to run with optimum precision and quality. We can cut all reflective materials.Metal forming

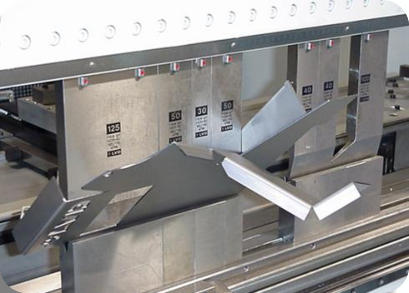

Our forming department is well equipped with multiple press brakes and a large panel bender. We can form anything from complex aerospace parts to structural components. Also utilizing our machines we can bump form large radius’s and cones. We have on hand a large assortment of forming dies and the capability to make specialty dies in house.

Tube and pipe bending

MWL has both tube bending and rolling capabilities. Angles, extrusions and tubes both square and round are no problem for us.Engraving

With YAG, C02, silk screen, acid etch and rotary engraving we are able to engrave all materials with fine detail and precision. From large to small. We also offer die cut vinyl lettering.Rolling

Rolling both large and small plates are no problem. We are equipped with different capacity rollers and heavy lifting equipment to get the job done.

Welding

Utilizing Inverter technology MWL is able to weld with consistency and precision. Whether it is a cosmetic fuse weld or a structural weld we are equipped to handle all of your needs. Certification and weld inspections can be provided upon request.Polishing

The lost art of metal polishing is found here at MWL Engineering. Our staff has the experience and ability to polish anything. We also specialize in pharmaceutical component restoration using our polishing and passivation process all done in house.Punching

With a huge library of dies, punching is one of the fastest ways of processing sheet metal. Although not as refined as laser cutting, it is still the perfect tool for production runs. We are able to punch louvers and countersinks. We can punch up to ¼” material.

Machine shop

MWL Engineering has a fully equipped machine shop for those complicated repairs and short production runs. Equipped with multiple lathes, mills both vertical and horizontal and surface grinding. We can handle any item.Finishing

Whether it is wet paint, powder coating, passivation or anodizing we can handle it all. We also specialize in designer coatings and reactive paint finishes. Our talented finishing department can also patina and age metals. We are able to color match all manufacturer color codes and we have camera match capabilities.Waterjet

The Waterjet process is capable of cutting any material and with our five axis head complex shapes are no problem. This method of cutting also leaves no heat affect zone.